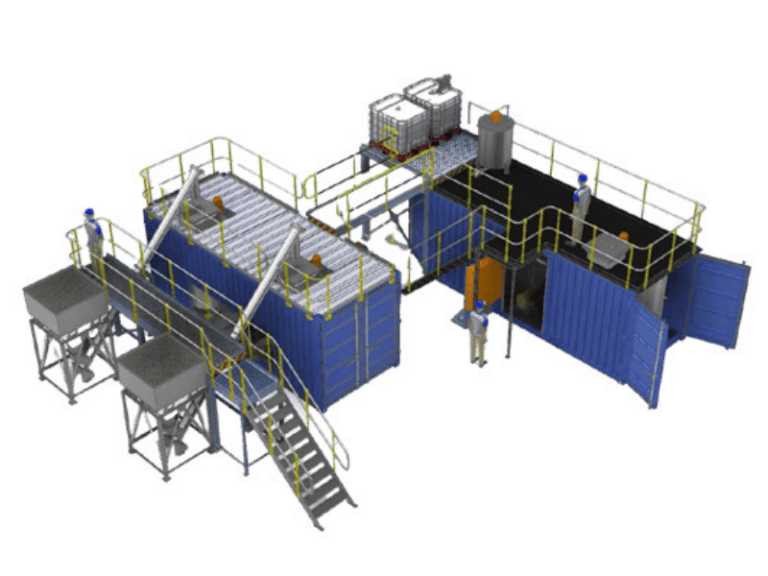

Modularised Emulsion Plant

BME Emulsion Plants are designed to be mobile, robust, and user friendly, making them ideally suited for the mining environment.

BME Emulsion Plants are designed to be mobile, robust, and user friendly, making them ideally suited for the mining environment.

Innovex Uphole is a bulk pumped booster-sensitive gassed emulsion. Innovex Uphole is a dual salt emulsion formulated with refined oils.

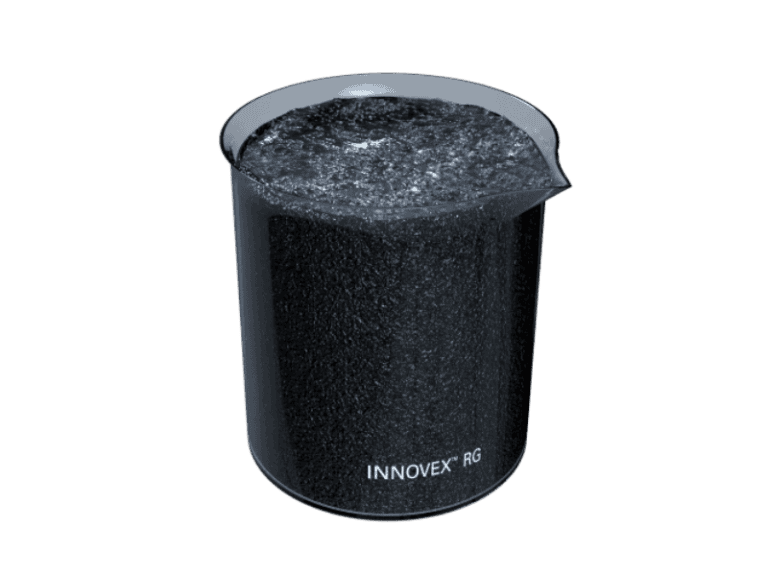

Innovex RG is a bulk pumped booster-sensitive gassed emulsion. Innovex RG is a dual salt emulsion formulated with reprocessed oil

Innovex Lateral is a bulk pumped booster-sensitive gassed emulsion. Innovex Lateral is a dual salt emulsion formulated with refined oils.

Innovex HE is a high energy bulk pumped booster-sensitive gassed emulsion. Innovex HE is a dual salt emulsion formulated with

Innovex C (Clear) is a bulk pumped booster-sensitive gassed emulsion. Innovex C (Clear) is a low viscosity dual salt emulsion

Innovex 300D is an industry-leading bulk explosives solution, delivered by mechanical equipment or device, for optimal performance in extremely challenging

Innovex 207 is a bulk pumped booster-sensitive gassed emulsion blend comprised of Innovex 100 or Innovex C (Clear) emulsion plus

Innovex 206 is a bulk pumped booster-sensitive gassed emulsion blend comprised of Innovex 100 or Innovex C (Clear) emulsion plus

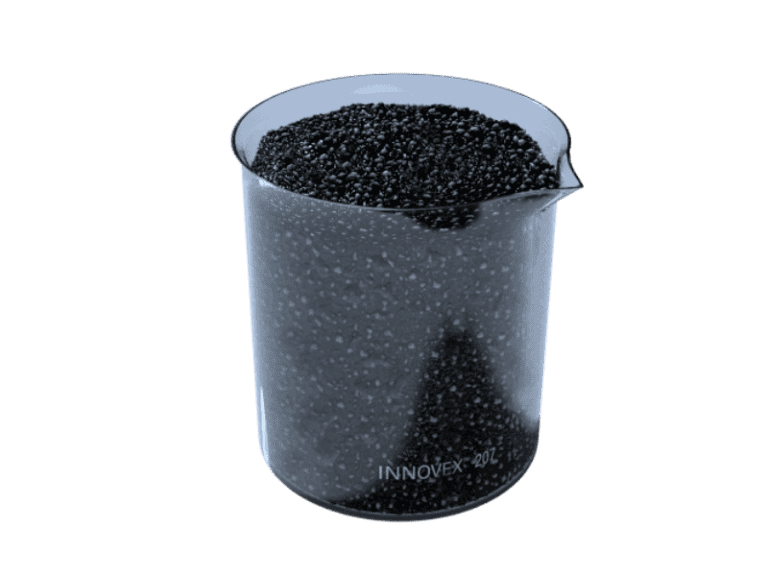

Innovex 205 is a bulk augered booster-sensitive Heavy ANFO comprised of Innovex 100 or Innovex C (Clear) emulsion plus Ammonium

Innovex 204 is a bulk augered booster-sensitive Heavy ANFO comprised of Innovex 100 or Innovex C (Clear) emulsion plus Ammonium

Innovex 203 is an augered booster-sensitive Heavy ANFO comprised of Innovex 100 or Innovex 100 C emulsion plus Ammonium Nitrate

Innovex 100 is a bulk pumped booster-sensitive gassed emulsion. Innovex 100 is a dual salt emulsion formulated with reprocessed oil

Innovex 207 HE is a bulk pumped booster-sensitive gassed emulsion blend comprised of Innovex 70 HE emulsion and un-oiled Ammonium

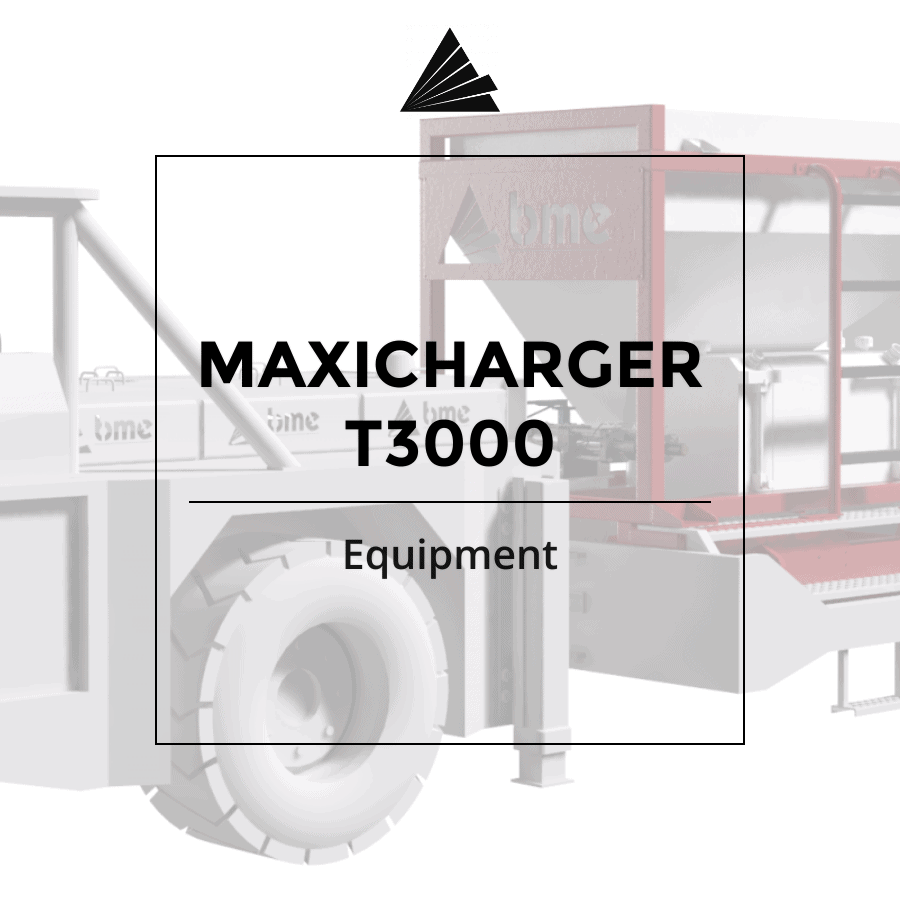

The MAXICHARGER is one of a range of compact charging systems developed for use with BME’s INNOVEX UG emulsion formulations. BME’s Mobile Pump Model 2 utilised on the MAXICHARGER is a positive displacement pump designed to deliver emulsion and sensitising solution simultaneously through the charging lance where it is sensitised to form an explosive on entering the blasthole.

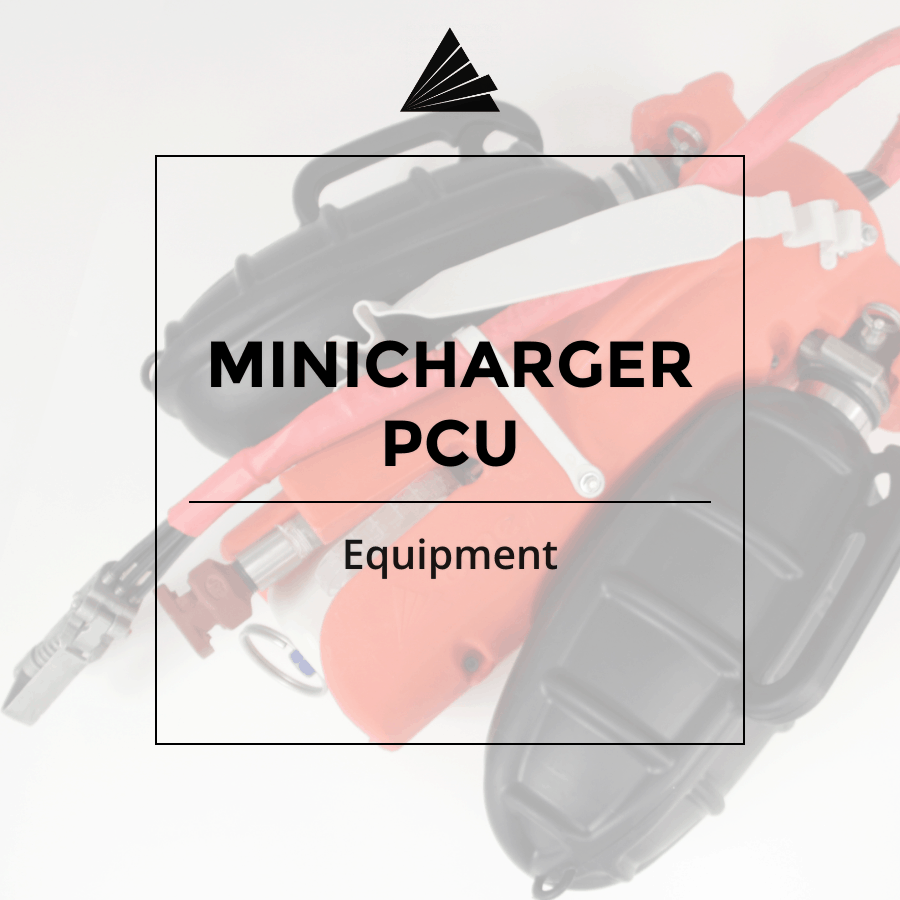

BME’s MINICHARGER PCU represents the forefront of pumpable emulsion technology available for use in narrow reef mining operations. BME’s PCU is designed in-house for the delivery of BME’s range of INNOVEX UG emulsion formulations, increasing the safety of daily blasting practices through their UN 5.1 classification.

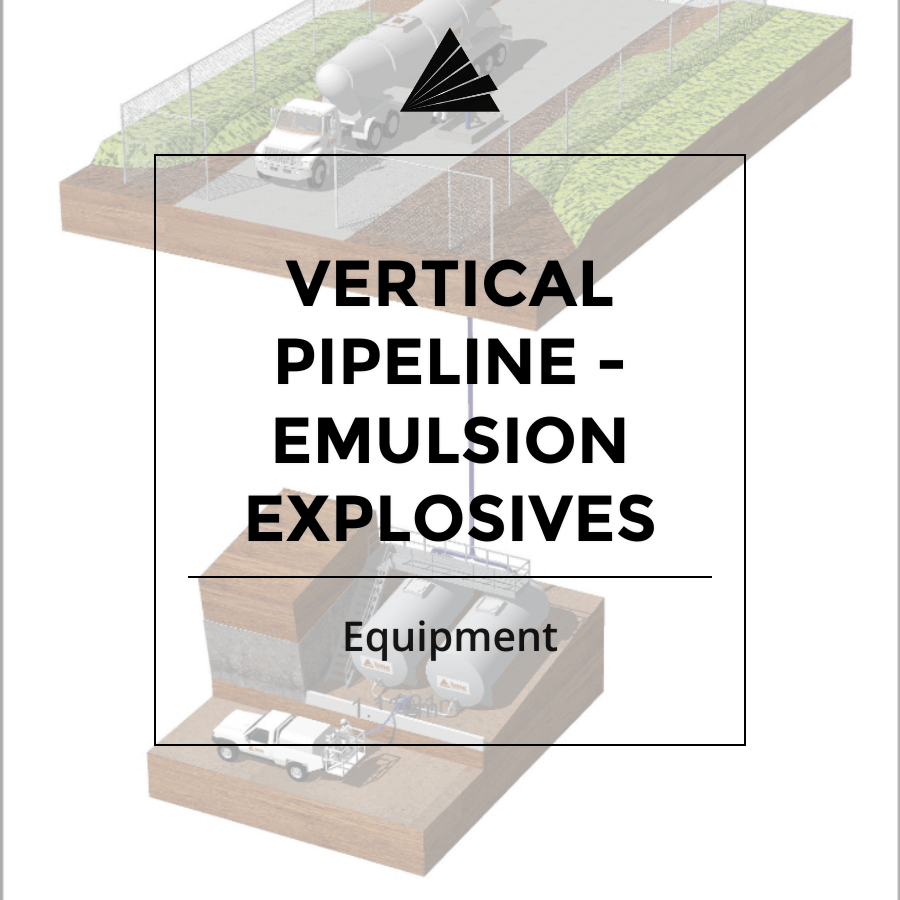

BME has designed a vertical pipeline system for the bulk transportation of non-sensitised base emulsion explosives from the surface to the underground workings of a mine.

The XPLOLOG pump controller is one of the electronic offerings that form part of the BME XPLOLOG underground electronic control and information systems. The pump controller is used to electronically control and monitor the delivery of emulsion from the charging vehicle to the face and is compatible with BME’s range of mechanised charging units.

BME’s MAXICHARGER represents the forefront of pumpable emulsion technology available for use in narrow reef mining operations. BME’s MAXICHARGER is designed in-house for the delivery in BME’s range of INNOVEX UG emulsion formulations, increasing the safety of daily blasting practices through their UN 5.1 classification. The MAXICHARGER is a positive displacement pump designed to work with BME’s patented ‘Closed Emulsion System’ but can be modified to run off a traditional emulsion tank set-up for larger development ends.

The Emulsion Charging Unit (ECU) is one of a range of mechanised charging systems developed for use with BME’s INNOVEX™ UG emulsions formulations. The unit is fitted with two mobile pumps allowing for maximum safety in charging operations and reduced down time.

The BME Electric Centralized Blasting System (CBS) provides continuous near real-time local system monitoring with remote access monitoring capabilities. The continuous monitoring feature built into the system ensures that an up-to-date Centralized Blasting System status and overview is available. This feature greatly improves the pre- and post-blasting decision making process.

BME’s industry-leading technology has been made possible through its class leading mobile pump technology in partnership with thought leaders in underground equipment manufacturing. Due to the light weight and low energy consumption of the mobile pump, it has been possible to develop a light weight, purpose built carrier to replace high capital, maintenance intensive carrier vehicles for use in underground mining operations.

BME’s Filling Station is designed to operate in conjunction with BME’s Portable Charging Unit (PCU) in narrow reef mining operations.

The Emulsion Charging Unit (ECU) is one of a range of mechanised charging systems developed for use with BME’s INNOVEX UG emulsion formulations. The unit is fitted with two mobile pumps allowing for maximum safety in charging operations and reduced down time.

BME Emulsion Plants are designed to be mobile, robust, and user friendly, making them ideally suited for the mining environment. All plants are divided into two primary systems. Steam generation to provide heat for the process and the production modules, which both generate the base solution from dry raw materials and manufacture the emulsions.

BME provides a technical support vehicle, fitted on a 4.2 l 4x4 Toyota land cruiser. The support vehicle is also retrofitted with roll over protection systems (ROPs) and the necessary requirements to operate on all surface mining operations. The technical support vehicle is fully equipped to provide full technical monitoring capabilities to enable client operations to optimise their blasting.

The Development Charging Unit (DCU) is one of a range of compact charging systems developed for use with BME’s INNOVEX UG emulsion formulations. BME’s Model 2 mobile pump utilised on the DCU is a positive displacement pump designed to deliver emulsion and sensitising solution simultaneously through the charging lance where it is sensitised to form an explosive on entering the blasthole.

BME’s Cruiser Charging Unit (CCU) is one of a range of compact charging systems available for use with BME’s INNOVEX range of emulsion formulations. The Model 2 CCU is fitted with BME’s new Mobile Pump Model 2 and Intelligent Control and Recording (ICR) System with recording and reporting functionality. This represents not only the forefront in mechanised emulsion technology, but significantly improves the safety of underground emulsion pump technology.

BME provides a stemming plant fitted on a Iveco 380 T42 WH 6x6 cab chassis or chassis specified by the client. The stemming truck is capable of delivering 15 to 18 cubic metres of crush aggregate. All stemming trucks are designed to operate in demanding environments encountered during normal mining operations. Design parameters to include all necessary safety control systems, as well as ease of operation, maintenance, and reliability. BME’s stemming trucks are SABS approved.

BME provides a full range of locally manufactured Mobile Manufacturing Units (MMUs), which cater for all surface mining and quarrying applications. BME MMUs are capable of pumping and auguring the full range of BME’s bulk explosives.

BME provides a full range of locally manufactured Mobile Manufacturing Units (MMUs), which cater for all surface mining and quarrying applications. BME’s MMUs are capable of pumping and auguring the full range of BME’s bulk explosives. All MMUs are designed to operate in the demanding environments encountered during normal mining operations.