BME, an Omnia group company, in collaboration with strategic partner Hypex Bio Explosives Technology, will present a paper on the benefits of hydrogen peroxide emulsion (HPE) in reducing atmospheric and aqueous pollutants associated with blasting. This presentation, “Breaking the Nitrate-Based Explosives Greenhouse: The Dawn of Production-Scale HPE for Industrial Blasting,” will feature at the upcoming 50th Conference of the International Society of Explosives Engineers (ISEE) in the United States.

HPE has garnered renewed interest in recent years as it offers a promising solution to eliminate NOx fumes from blasting. With an increasing number of companies committing to the COP26 Net Zero goals by 2050, there is a growing impetus to explore hydrogen peroxide-based explosives for industrial use.

“The past decade has seen renewed interest in hydrogen peroxide emulsion as a route to eliminating NOx fumes from blasting. As more companies have committed to the COP26 goals of Net Zero by 2050, there is additional impetus to investigate hydrogen peroxide based explosives for industrial use.”

Dr. Scott Scovira

BME’s Global Manager Blasting Science and Engineering

One notable advantage of HPE is its absence of nitrates, which means it does not generate post-blast NOx. It also avoids aqueous nitrate and ammonia pollution, aligning with stricter regulations on mine site water discharge limits.

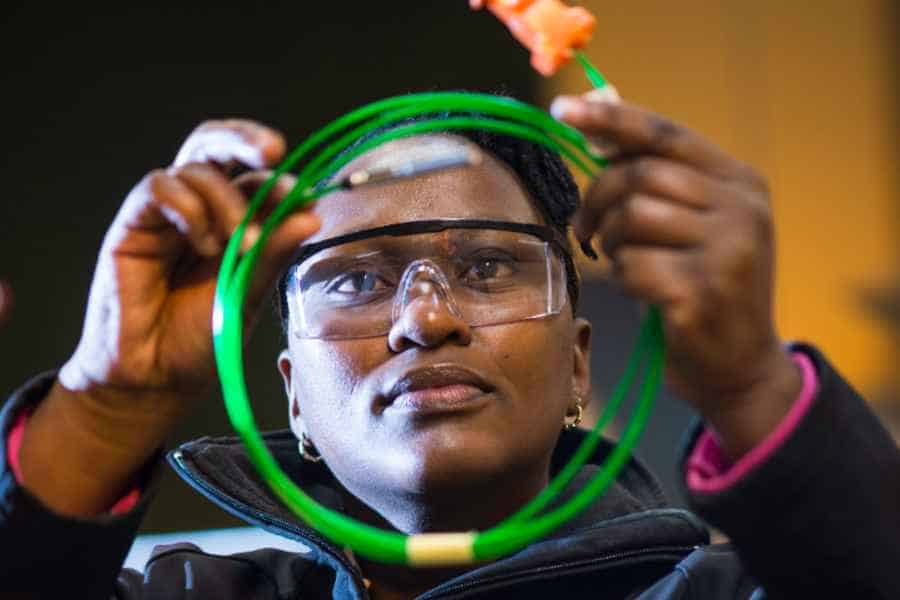

Hypex Bio has pioneered the formulation, manufacture, and industrial-scale delivery of hydrogen peroxide-based emulsion. Thomas Gustavsson, CEO of Hypex Bio, stated that the performance of HPE matches that of nitrate-based emulsions and is compatible with existing priming and initiation systems. A successful underground HPE evaluation was recently conducted with a major mining company in Sweden, showcasing equivalent rock breakage, advance, muck displacement, and excavator performance. The absence of hazardous fumes resulted in reduced ventilation and re-entry times during the assessment.

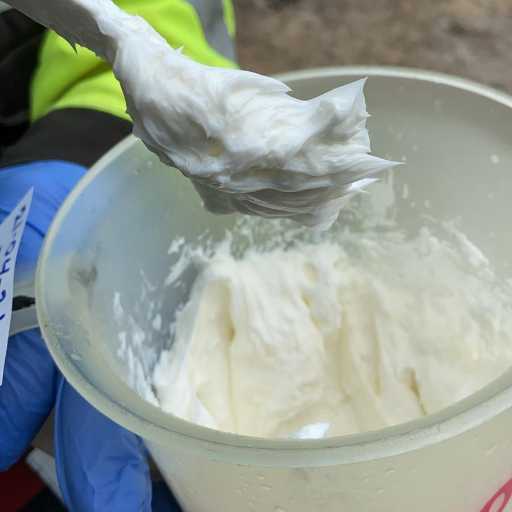

Energy efficiency is another advantage of HPE production. The base HPE is manufactured in a low-energy-intensity modular plant using proven mixing techniques. In contrast, the production of ammonium nitrate (AN) emulsion is relatively energy-intensive and not carbon-neutral.

Nitrate-free ammonia = 90% reduction in carbon dioxide

Compared to nitrate-based explosives, HPE significantly reduces total carbon emissions. Based on the European Union average, 1 kg (2.2 lb) of AN emulsion emits 2.3 kg (5.1 lb) of carbon dioxide for the oxidizer phase only. In contrast, the production of HPE emits just 0.23 kg (0.5 lb) of carbon dioxide, marking a substantial 90% reduction.

Omnia entered into a strategic partnership with Hypex Bio in October 2023 and holds a minority equity stake in the company.

To learn more about the potential of hydrogen peroxide emulsion and its environmental benefits, book an online consultation with D. Scott Scovira by clicking here.

Originally Posted in Mining Weekly.