Mining companies worldwide are increasingly focused on enhancing their environmental, social, and governance (ESG) performance. As part of this commitment, they are exploring new technologies and strategies that offer improved safety and environmental advantages. One such development in the mining sector is the use of dual salt emulsions in blasting operations.

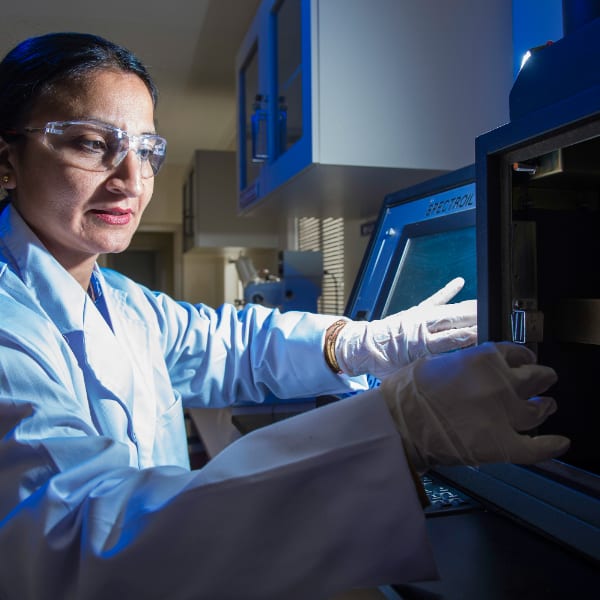

Dr. Rakhi Pathak, global product manager for BME, gave a talk on the advantages of using dual salt emulsions at the 7th Drill & Blast Down Under conference in Queensland, hosted by the Australian chapter of the International Society of Explosives Engineers. Her technical paper sheds light on the concept, constituents, and superior performance of BME’s dual salt emulsions.

“Dual salt emulsions have proven themselves as less harmful in terms of potential nitrate contamination and greenhouse gas emissions. At the same time, they can be transported long distances and pumped multiple times before use, while still delivering the improved performance benefits, including high energy in a blast.”

– Dr. Rakhi Pathak, BME’s global product manager

Transforming Safety and Environmental Impact

Dual salt emulsions are less harmful in terms of nitrate contamination and greenhouse gas emissions than single salt emulsions. Dr. Pathak highlighted that these emulsions can be transported long distances, pumped multiple times, and still provide improved performance, such as high energy in an explosion.

Inhibiting Crystallisation

One notable advantage of dual salt emulsions lies in their reduced potential for crystallisation. Adding calcium nitrate to the emulsion mixture, with its more cubic shaped crystals, greatly diminishes the chances of crystallization. This not only prolongs the life of the emulsion, but also enhances its overall performance.

Energy Efficiency

The manufacturing process of cold emulsion requires lower temperatures (65 degrees) compared to single salt emulsions (85 degrees), which leads to significant energy savings. Reducing cooling times has two benefits. First, it helps the environment by promoting sustainability. Second, it improves efficiency in manufacturing and supply chain processes by reducing the time needed for handling and transporting the emulsion.

“Cold emulsion is manufactured at just 65 degrees – considerably lower than the 85 degrees used for single salt emulsion. This has energy-saving benefits as less heat is required.”

– Dr. Rakhi Pathak, BME’s global product manager

Addressing Harmful Gases and Nitrate Contamination

Harmful gases emitted during mining blasts are a growing concern in the industry. Dr. Pathak stressed the importance of carefully adjusting the proportions of the oxidizer (ammonium nitrate and calcium nitrate) and fuel in emulsions. This is to guarantee the absence of any harmful gases being generated during an explosion. Dual salt emulsions are beneficial because they can be adjusted to reduce the release of harmful fumes, thus protecting miners and communities living near open-pit mines.

These emulsions greatly reduce nitrate leaching, which helps minimise the environmental impact and compliance risks associated with mining operations.

“The chemical composition of dual salt emulsions can be easily optimised to minimise the generation of harmful gases.”

– Dr. Rakhi Pathak, BME’s global product manager

Enhanced Performance

Dispelling a common misconception, Dr. Pathak addressed the belief that single salt emulsions deliver greater energy in a blast. Experiments conducted on various single salt emulsion systems showed limited comparability due to disparities in software usage among different suppliers.

After conducting extensive field tests using various suppliers’ products in the same conditions, it was discovered that there is very little or no noticeable variation in energy performance between single and dual salt emulsions. Dr. Pathak emphasised the importance of field tests using different suppliers’ products under identical blasting conditions to accurately evaluate performance.

Addressing Reactive Ground Challenges

Dr. Pathak emphasised that dual salt emulsions have better resistance to reactive ground conditions compared to single salt products because they contain less ammonium nitrate.

Highlighting the increased resistance, she pointed out that BME’s specific emulsifier and utilisation of recycled oil as a fuel agent enhance this benefit even more. By using dual salt emulsions with the inclusion of urea, blasters can access a safe window for loading and shooting.

By way of example, BME sent 4,000 tonnes of emulsion to St. Helena for a significant civil engineering project. This emulsion endured up to 10 pumping cycles, extended transportation on road and sea, and varying climatic conditions. Despite these challenges, the product performed well, meeting customer expectations.

This shows that mining operations can boost productivity and fulfil ESG obligations by reducing environmental impact through the implementation of dual salt emulsions.

“Even after enduring these conditions, the product performed on site in line with customer expectations.This showed that a double salt emulsion explosive can enhance the productivity of mining operations, including other sectors, while delivering the environmental benefits that miners are looking for.”

– Dr. Rakhi Pathak, BME’s global product manager

BME’s Commitment to Advancement

BME is dedicated to ESG, innovation, and quality. Our transformative dual salt emulsions are pushing boundaries and driving positive change in the mining industry.

By engaging in global projects and fostering collaborative efforts, BME is reshaping the mining landscape, heightening awareness, setting itself apart from competitors, and forging robust relationships with customers, partners, and regulators.

If you are a mining professional, thought leader, or stakeholder interested in collaborating with us to shape a sustainable and innovative future for African mining.

To learn more about the transformative power of dual salt emulsions, read the full article on International Mining by clicking here.