Blast better for greener results – BME

Not only do poor blasting practices erode mines’ financial bottom lines – they are also bad for the environment, according the BME technical director Tony Rorke.

AI-driven blast optimisation and performance delivery.

Xplosmart represents the next evolution in BME’s digital ecosystem — a smarter, AI-enabled platform engineered to reshape the future of blasting and mining efficiency. Powered through our collaboration with Strayos, Xplosmart integrates high-resolution imagery, geospatial data, machine learning and automation to deliver intelligent insights from pit to plant.

The result is a new standard in precision, safety, enablement and cost optimisation for mines seeking a competitive edge in an increasingly data-driven industry.

The platform is updated throughout the year with new capabilities that remove information silos and connect teams across the mine-to-mill workflow. You gain access to the latest digital tools without disruption.

Xplosmart runs on a high-security cloud platform that protects your data and keeps full control in your hands. All blast and performance data is stored in your own account on trusted global infrastructure.

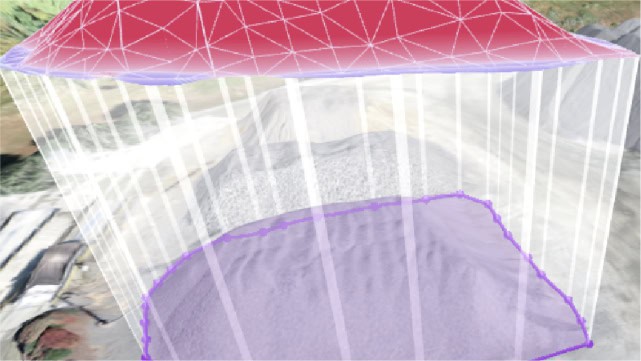

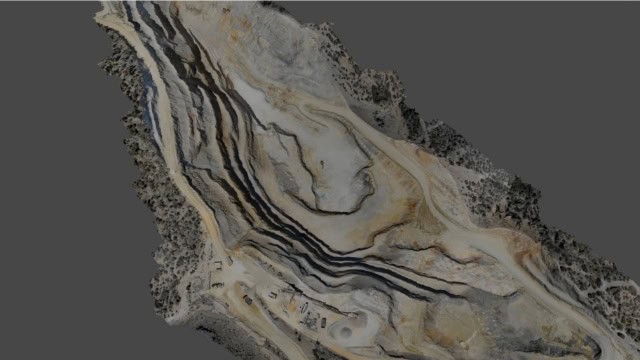

Xplosmart automatically processes visual, sensor and geospatial data into accurate 3D models and digital twins within minutes. Clear analytics help teams make better decisions faster.

Advanced machine learning analyses millions of data points to improve blast outcomes in real time. Insights are calibrated to your site conditions to support safer, more cost-efficient and productive blasting.

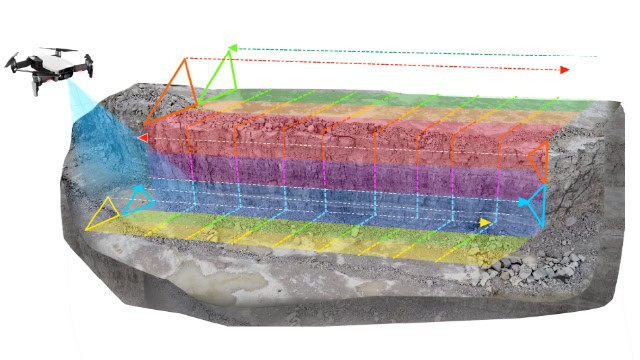

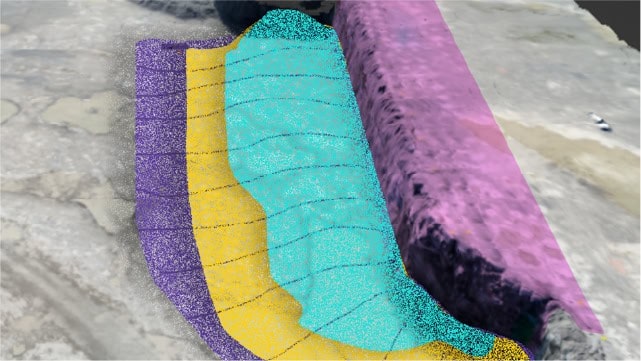

3D Photogrammetry.

Create highly detailed digital representations of your pits, benches, or entire site using mining-grade AI photogrammetry.

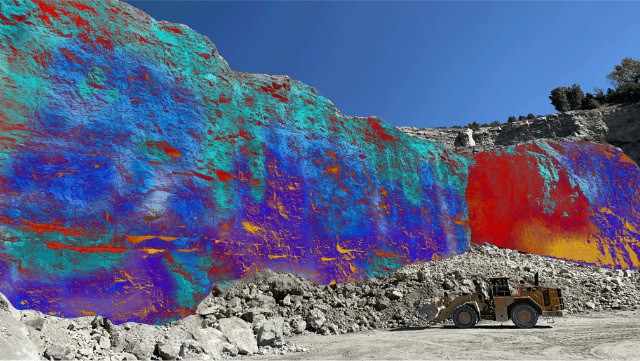

Hyperspectral Imaging AI.

Improve recovery and reduce dilution by using AI to classify mineral zones across benches, muckpiles, or the broader operation.

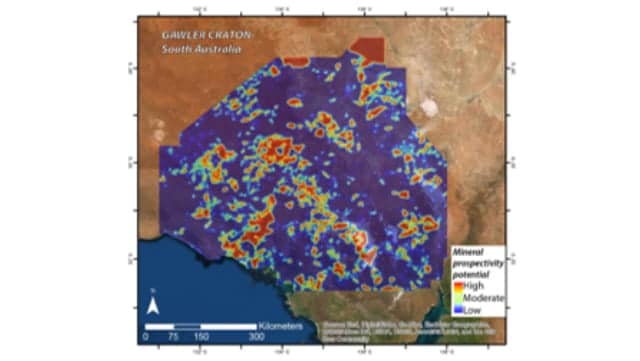

Ore Deposit Prediction.

Reduce exploration costs by utilizing AI models that predict potential ore body locations prior to the commencement of drilling.

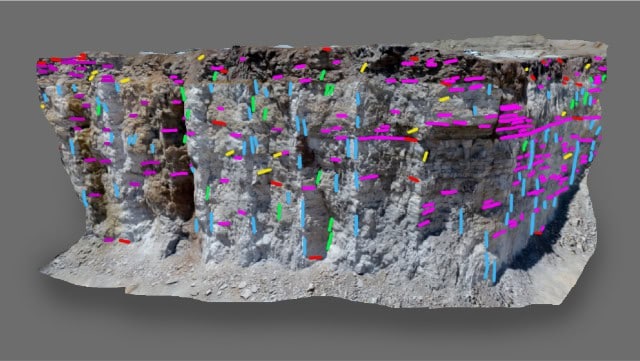

Face Profiling.

Measure 3D burdens for each hole. Pre- or post-boretracking to improve fragmentation and reduce the risk of flyrock.

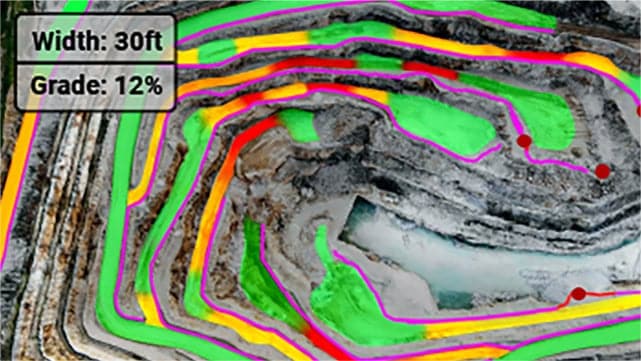

Drill Pattern Design.

Automate shot plan development with tools that optimise energy distribution and support consistent blasting outcomes.

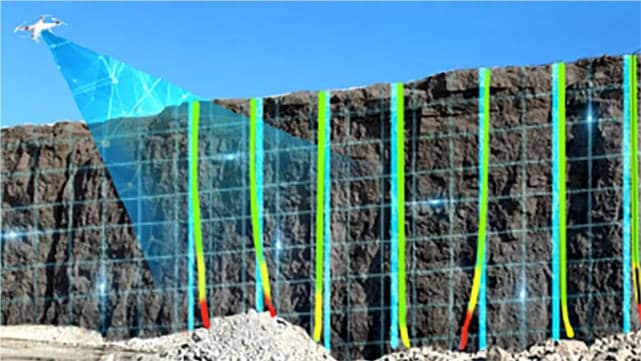

Smart Drill Data Integration.

Send pattern designs directly to Smart Drills and receive Measure-While-Drilling data for real-time geological insight.

Borehole Data Integration.

Combine borehole intelligence with your 3D drone models to achieve better fragmentation control and reduce flyrock.

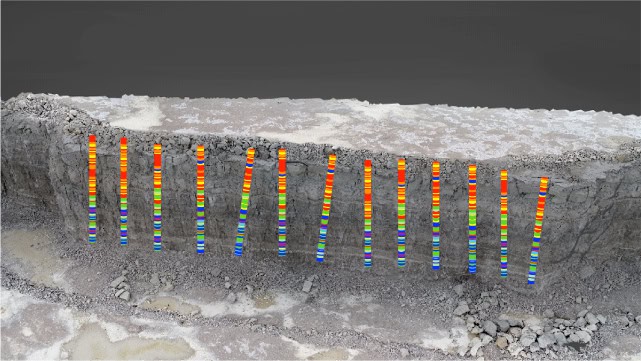

Blast Hole Loading Design.

Customise loading and timing with hole-specific data, including geology and 3D burden measurements.

Blast Hole Timing Design.

Design timing sequences tailored to individual hole conditions for more precise blast performance.

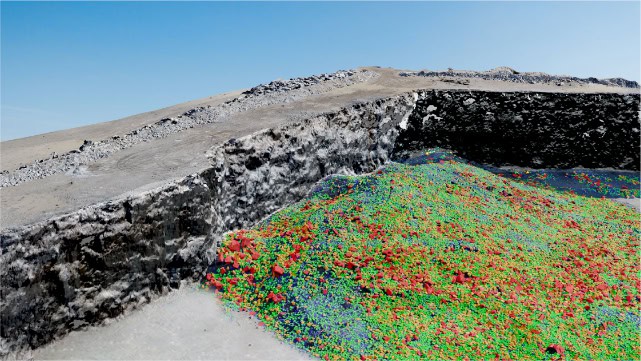

Fragmentation AI.

Automatically analyse 2D or 3D fragmentation using drone footage, handheld images, or equipment-mounted cameras. Improve future blasts with prediction models that learn from operational history.

Muckpile Movement AI.

Measure cast percentage, throw distance, trough depth, and other muckpile dynamics using automated AI analysis. Use predictive models to refine future designs.

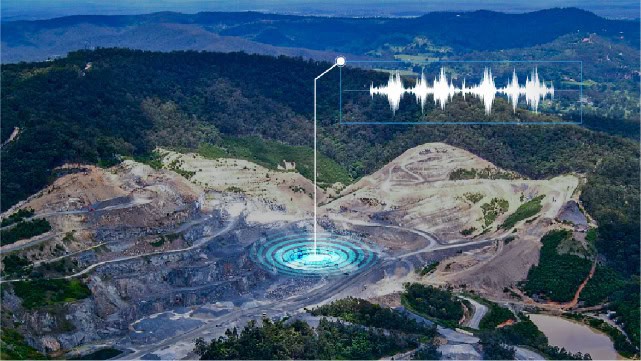

Vibration and Airblast Modelling.

Centralise vibration and airblast data alongside your blasting designs to automatically generate accurate, site-specific prediction curves.

Not only do poor blasting practices erode mines’ financial bottom lines – they are also bad for the environment, according the BME technical director Tony Rorke.

The revolutionary transition from non-electric to electronic delay detonators (EDDs) in the field of blasting has brought many benefits to mining productivity, but there are still plenty of advantages to be gained by blast pioneers who are prepared to think ‘outside the box’.

The powerful combination of mobile computing and ‘cloud’ data storage is starting to transform safety and productivity on mines that embrace technology, according to BME senior software developer Nicky Klacar.