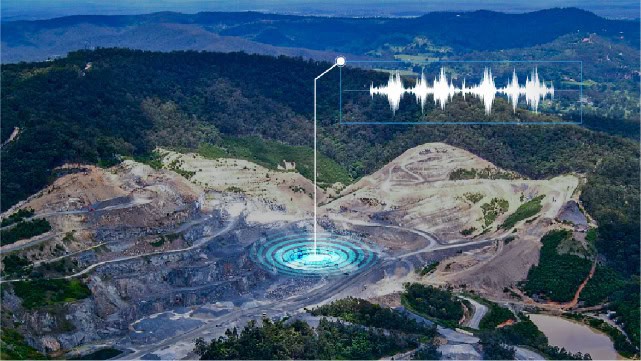

Another SA blasting record for BME

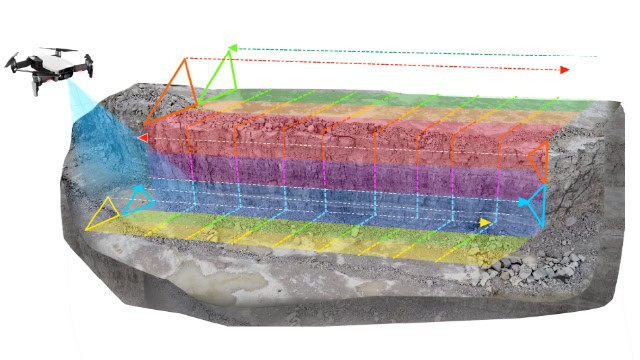

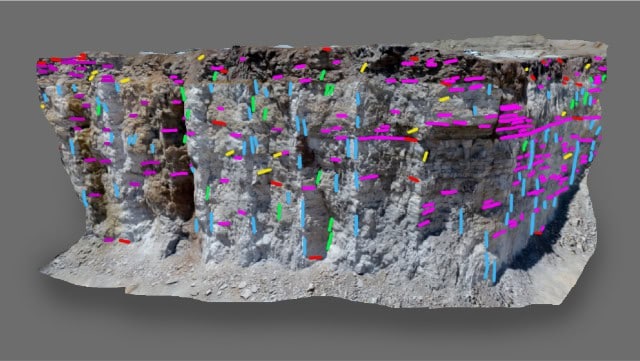

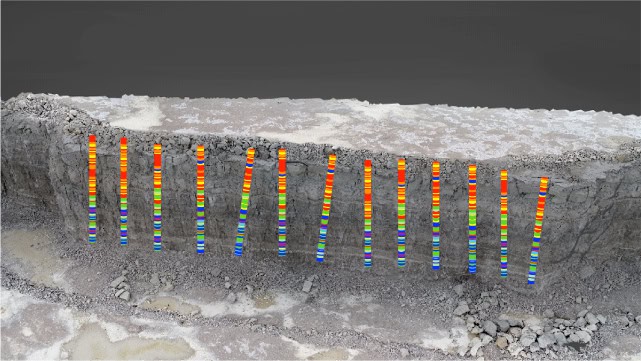

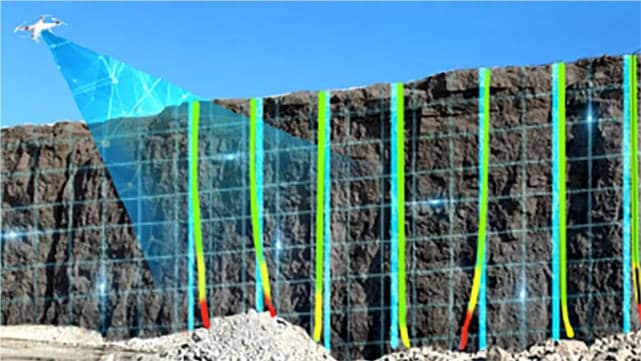

24 August, 2020, Johannesburg – BME, a member of the Omnia Group has broken the South African record for the largest electronic detonator blast, initiating 3,780 detonators in a single blast at a manganese mine near Hotazel in the Northern Cape.