Viperdet SD non-electric detonators are designed to provide reliable sequential initiation of explosives charges in underground narrow reef stoping applications.

Viperdet Dual non-electric detonators must not be used in flammable environments such as methane or coal dust.

Viperdet non-electric detonators are safe against extraneous electric currents except lightning.

Detonator strengths: High strength No. 8 in-hole detonator. Low strength No. 3 surface detonator.

Delay timing: In-hole detonator = 3800ms. Surface detonator = 200ms.

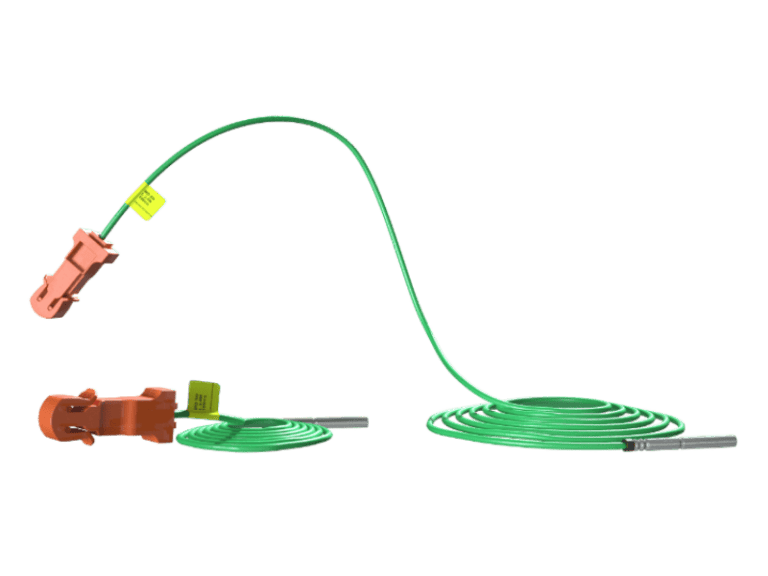

Shock tube: Extruded polyethylene exterior over surlyn inner with minimum of 19 kg (41 lb) tensile strength.

Connector: T-clip ratchet connector. The connector can hold up to 4 shock tubes and is designed to ensure reliable initiation, while minimising shrapnel damage to the shock tube.

Viperdet Dual SD non-electric detonators can be used to prime the full range of BME's detonator sensitive explosive products.

To prevent a snap, slap, and shoot incident (unexpected detonation) never pull or stretch non-electric shock tube to the point of breaking.

This product may be used in ground temperatures up to a maximum of 65 °C (150 °F). If the application requires use outside of this temperature range please contact a BME Technical Representative for additional guidance.

The recommended maximum sleep time is 21 days. If the application requires longer in-hole sleep time, please consult with a BME Technical Representative for guidance.

Product Risk Profile

All explosives are classified as dangerous goods and may cause damage to property, personal harm, or death, if not used correctly.

Severe detonation hazard when exposed to heat.

Detonation may occur from impact, friction, or excessive heating.

Never attempt to fight explosives fires.

Transportation

All explosives must be transported in accordance with relevant local, state and federal regulations.

Viperdet Dual SD shelf life is 36 months when stored in the original packaging, under dry conditions and moderate temperate, and in a well ventilated and approved magazine.

All explosives must be stored in accordance with relevant local, state and federal regulations.

Units are placed in plastic inner packaging that is heat sealed and packed in boxes.

Other lengths are available on request.

| Length | Units/box |

| 2.1 m | 400 |

| 2.4 m | 350 |

| 3.0 m | 350 |

| 3.6 m | 300 |

| 4.2 m | 250 |

| 4.8 m | 250 |

Class

1.1B, UN No. 0360, DETONATOR ASSEMBLIES, NON-ELECTRIC.

1.4B, UN No. 0361, DETONATOR ASSEMBLIES, NON-ELECTRIC.

1.4S, UN No. 0500, DETONATOR ASSEMBLIES, NON-ELECTRIC.

In case of emergencies, click here to contact our team for assistance.

Omnia disclaims all liability whatsoever, whether arising in contract, delict (including negligence) or otherwise in relation to the use of any products/solutions or services and all implied warranties, terms and conditions relating to the products/solutions or services (whether implied by statue, common law or otherwise), including (without limitation) any warranty, term or condition as to accuracy, completeness, satisfactory quality, performance, fitness for purpose or any special purpose, non-infringement, information accuracy, as between Omnia and you, are hereby excluded. Omnia specifically disclaims liability and will not be responsible for, any liability or damages, howsoever arising, resulting from the use or reliance upon the information in this document.

You assume sole responsibility for results obtained from the use of the products/solutions or services, and for conclusions drawn from such use.

We continuously update our technical data sheets to reflect the most current and accurate information based on the latest available data. As such, the information provided is subject to revision. We recommend regularly checking for updates to ensure you are accessing the most up-to-date technical details.