Underground Control System

BME’s advanced charging unit control system is at the heart of the charging unit and the charging operation. It allows for flexibility and accuracy at

BME’s advanced charging unit control system is at the heart of the charging unit and the charging operation. It allows for flexibility and accuracy at

BME provides a technical support vehicle, fitted on a 4.2 L 4×4 Toyota Land Cruiser or vehicle specified by the customer.

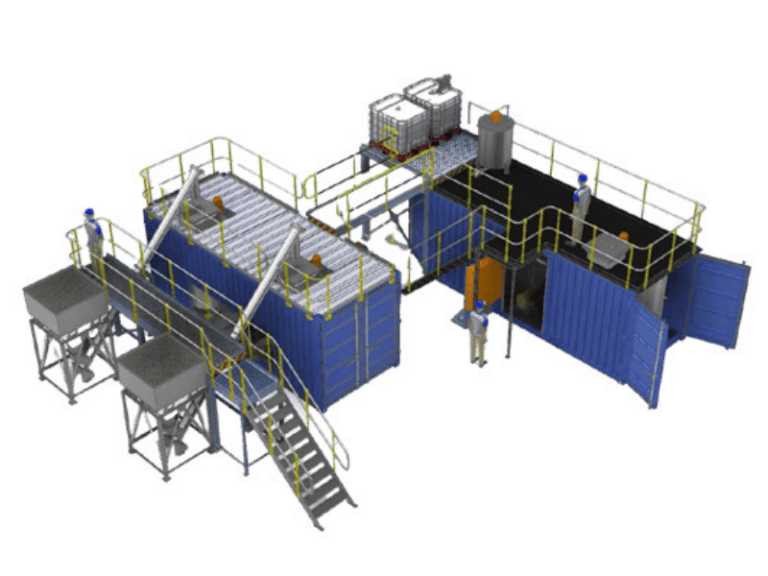

BME Emulsion Plants are designed to be mobile, robust, and user friendly, making them ideally suited for the mining environment. All plants are divided into

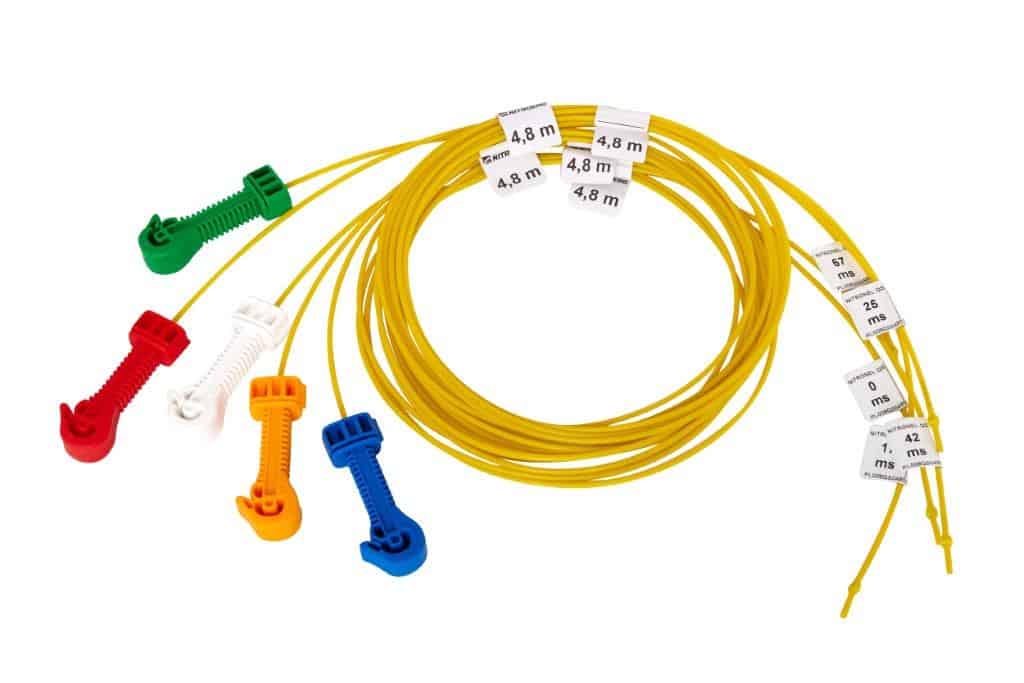

Initiation system. Non-Electric Detonator Surface Connector. The Viperdet QS series permits blast sequencing by introducing intervals of delay times in between blast holes through the

BME provides a stemming plant fitted on an Iveco 380 T42 WH 6×6 cab chassis or chassis specified by the customer.The stemming truck is capable

BME Provides a full range of locally manufactured Mobile Manufacturing Units (MMUs), which cater for all surface mining and quarrying applications. BME’s MMUs are capable

BME’s Cruiser Charging Unit (CCU) is a compact charging system designed for Innovex emulsion formulations.Equipped with an MP2 pump and an Intelligent Control System, it

BME Provides a full range of locally manufactured Mobile Manufacturing Units (MMUs), which cater for all surface mining and quarrying applications. BME’s MMUs are capable

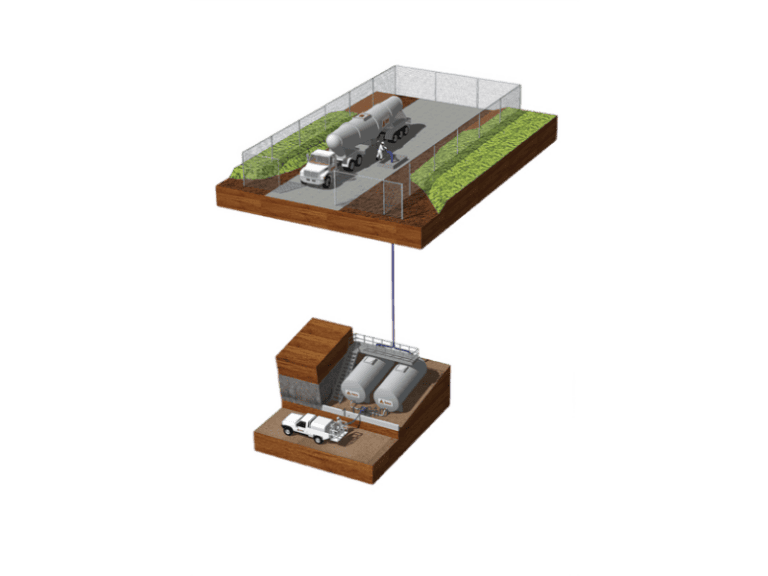

BME’s Vertical Pipeline, allows the transfer of Emulsions from surface or surface storage silos to underground storage silos and/or transfer units.

BME’s Horizontal Storage Silos are robustly designed and built to withstand the harsh surface conditions on mines, while BME’s Innovex UG emulsions are stored in