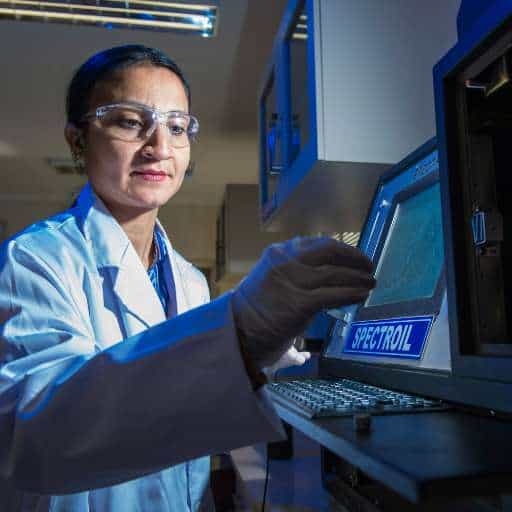

BME, a leader in mining solutions, has launched the Viperdet MS Series, an advanced range of non-electric detonators for the quarrying sector. Leveraging automated production lines and a certified supply chain, these detonators offer exceptional quality and reliability. BME’s investment in production technology, including robotics and artificial intelligence, ensures consistent and high-performance detonators that meet and exceed customer expectations.

The Viperdet MS Series sets BME apart from competitors with its high level of automation. Compared to manual production lines, BME’s automated processes enable enhanced safety, production flexibility, reduced waste, and minimized environmental impact. The company’s dedication to sustainability is demonstrated by its use of renewable energy to power production facilities.

Designed for optimal blasting and fragmentation outcomes, the Viperdet MS Series includes downhole, trunkline, and dual detonators. These detonators feature a triple-layered shock tube for maximum strength and protection during normal operating conditions. The connectors, made with temperature-resistant, high-strength material, ensure ease of use and quick application. BME’s stringent quality control processes and adherence to industry safety standards prioritize safety.

With a certified supply chain and rigorous testing, BME guarantees exceptional quality in the Viperdet MS Series. In-house manufacturing allows close monitoring of product quality, ensuring reliability and high accuracy in delay timing. By introducing the Viperdet MS Series, BME aims to capture a significant market share within the quarrying sector, offering top-notch detonators that deliver superior blasting results.

Click here to view the full article on Quarrying Africa >

https://quarryingafrica.com/quality-is-the-watchword-for-bmes-new-viperdet-detonators/