Mines’ technology push means new approaches to digitisation

As mining companies increasingly look to new technologies to improve their productivity, they are starting to think differently about how they approach digitisation and automation.

Blasting solutions that take mines into digital age

As mining companies rapidly shift their strategies and operating models to leverage digital transformation, new technologies in blasting and explosives are making an ever more vital contribution to bottom-line improvements.

Creating Tomorrow’s Future Leaders Today: BME hands over mobile science lab to Merafong Community

On Wednesday, 13 February, two high schools in the Merafong Community were the proud recipients of a school mobile laboratory. The initiative results from a close collaboration between the Mayor’s Office at the Merafong City Local Municipality and BME.

BME’s Africa offerings and focus on show at Indaba

South Africa-based explosives leader BME will be showcasing its African presence, expertise and technology at the 2019 Investing in African Mining Indaba from February 4 to 7 in Cape Town; it will also highlight its strengthened presence in West Africa, which is poised to become one of the top five gold-producing regions in the world.

BME supports Zambia’s success in copper and more

As Zambia’s copper mining focus shifts west from Kitwe, Ndola and Chingola to the growing operations at Solwezi and Kalumbila, blasting leader BME supplies some of the largest minerals operations in the country – with further potential for growth across the border in the Democratic Republic of Congo (DRC).

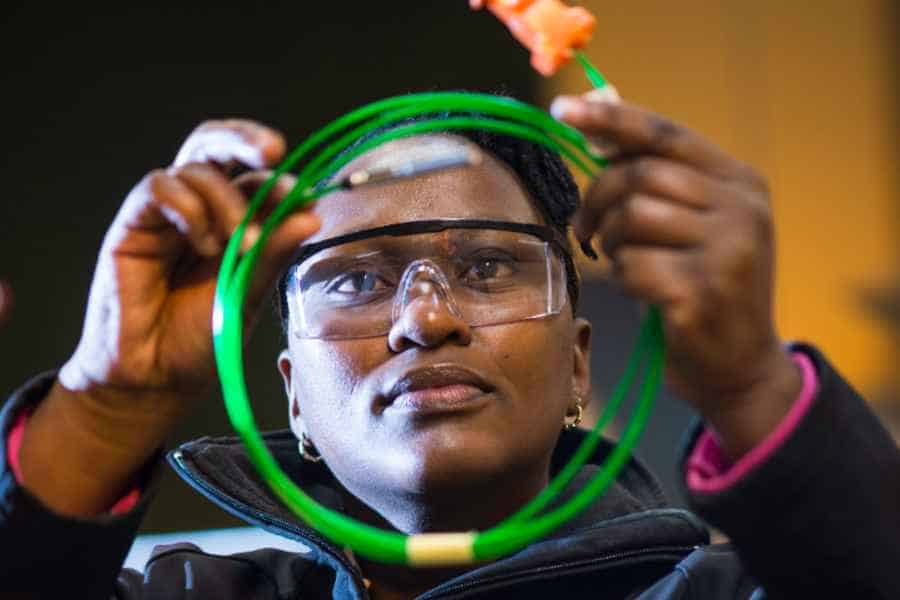

Real-time blast block data reporting from BME

Getting real-time data from a blast block during drilling, charging and stemming operations is difficult with traditional manual reporting systems – but BME’s XPLOLOG system has changed all that.

Blast better for greener results – BME

Not only do poor blasting practices erode mines’ financial bottom lines – they are also bad for the environment, according the BME technical director Tony Rorke.

Cullinan Diamond Mine, BME in collaboration for safer blasting, value optimization

Cullinan Diamond Mine, owned and managed by Petra Diamonds since 2008 and previously known as Premier Mine, is located to the east of Pretoria. The mining operation is rich in South African history as mining commenced in 1903, it employed ±14 000 people at the time of World War I and produced the 3 106 carat gem diamond, the world’s largest gem diamond to date.

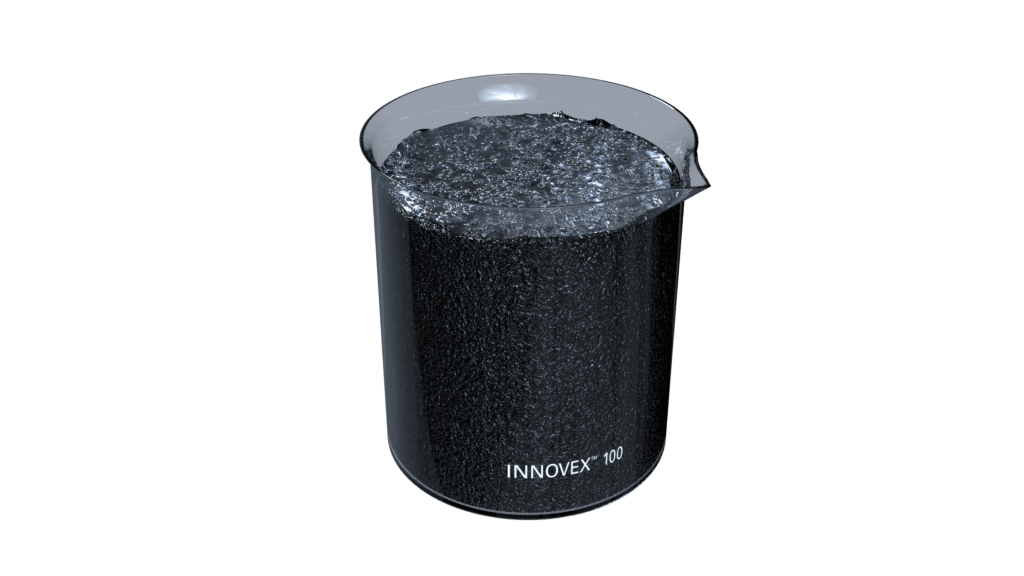

Innovex is BME’s new emulsion brand

After more than three decades of product evolution and advancement in its emulsion offerings, South Africa-based explosives leader BME is subsuming its well-known brands such as HEF, and Megapump under the name of Innovex.

Next step into Australia as BME acquires balance of AIS

Explosives leader BME (JSE Omnia group) has completed the acquisition of Australia-based Advanced Initiating Systems Pty Ltd (AIS), a company that BME was instrumental in establishing five years ago; the move signals a rebranding and expansion of BME’s technical services and products in Australia.