BME Metallurgy drives green chemistry for sustainable mining

Environmentally responsible chemical practices demand an integrated approach from mines, across the mining value chain, with hydrometallurgy included, according to Daniel Verwey, Business Development Manager at Omnia Holdings company BME Metallurgy. Verwey said mining companies are increasingly searching for practical ways to reduce the risks associated with chemicals in applications, such as leaching, flotation, metal […]

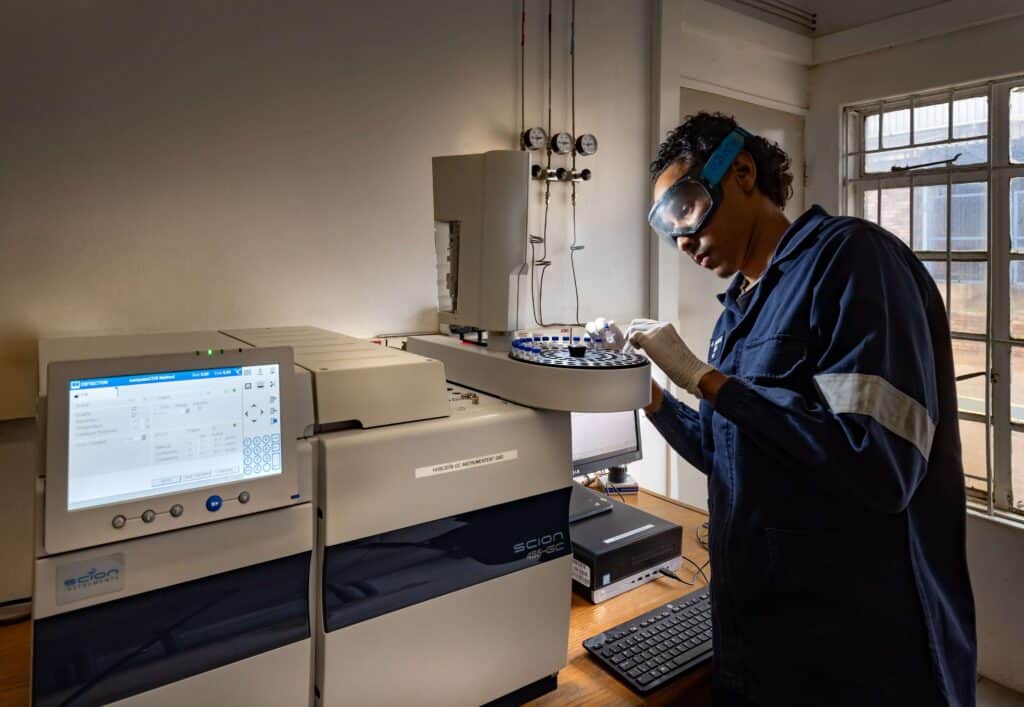

BME proves a unique solution for colloidal silica in leaching

Metallurgy has succeeded in developing and applying an innovative solution that promises potential in other commodity segments. According to Daniel Verwey, Business Development Manager at BME Metallurgy, colloidal silica can cause serious operational issues in hydrometallurgical plants and particularly in solvent extraction. “For many years, process plants have grappled with the impacts of silica, a […]

Video: BME Mining Technical Summit Event

Watch the full BME Technical Summit 2025 recording from 22 October 2025, where global mining leaders and experts discussed cutting-edge blasting technology, digital mining solutions, and operational excellence. Discover key insights on sustainability, safety innovations, responsible business practices, and technology-driven performance—all reflecting BME’s dedication to integrity, innovation, and long-term value in mining. BME sets industry […]

BME and Strayos alliance optimises blasting with AI-driven insights

Omnia Holdings company BME has strengthened its blasting software offering beyond its premium Blastmap blast planning platform through a new partnership with technology leader Strayos. This alliance brings together BME’s blasting expertise and Strayos’ advanced image processing and artificial intelligence (AI) capabilities, delivering enhanced functionality, precision, and next-generation software solutions to the mining industry. XPLOSMART, […]

Detonator plant a first step in BME Mining Canada’s local complex

Having completed its local electronic detonator manufacturing plant – only the second such plant in Canada – BME Mining Canada is forging ahead with a range of facilities to produce blasting-related offerings for the mining, quarrying and construction sectors. According to Neil Alberts, General Manager at BME Mining Canada, its development site outside Nairn Centre, […]

BME’s underground blasting innovations improve fragmentation and reduce mining costs.

The close correlation between fragmentation size and mining costs has often been overlooked by mines, said Derick Menezes, Regional Manager: Underground Operations at BME, in a recent webinar. “Both extra fine and excessive forced rock fragmentation increase total mining costs,” said Menezes. “However, by aligning fragmentation size and distribution with the capabilities of existing loading, […]

BME shares insights at Creamer Media’s Mining Technology Webinar

BME’s GM for Technology and Marketing, Nishen Hariparsad recently participated in Creamer Media’s Mining Technology Webinar, held on 27 August 2025. The webinar focused on how emerging technologies are helping mines enhance productivity, efficiency, and sustainability. Nishen highlighted BME’s role in advancing digital blasting technologies and providing integrated solutions that deliver value across the mining […]

Empowered women make their mark in mining explosives industry.

Omnia Holdings company BME is growing and developing women to contribute substantially to the business and the mining industry it serves. Monica Matomane is a Production Manager for the Initiating Systems lines, Electronic Delay Specialist and Mining Explosives Leader, and is the first black woman in this position at BME. She oversees the progression of […]

BME AXXIS technology facilitates complex pit design change

The blasting expertise of BME’s AXXIS Product Support and Global Blasting Technical Services (GBTS), together with the drill and blast team at an open-cut metallurgical coal mine, successfully implemented complex pit design changes. This collaboration enabled the adoption of a more efficient blasting method, significantly enhancing operational efficiency. This project was essential to overcome the limitations […]

BME reaffirms commitment to delivering sustainable mining solutions

By reliably employing used oil, a hazardous waste, as a key raw material in the manufacture of its standard bulk emulsions, Omnia Holdings company BME is striving to deliver sustainable, future-fit solutions through innovation and precision. This is according to Sachin Govender, Used Oil Manager at BME, who highlighted how the company is incorporating used […]