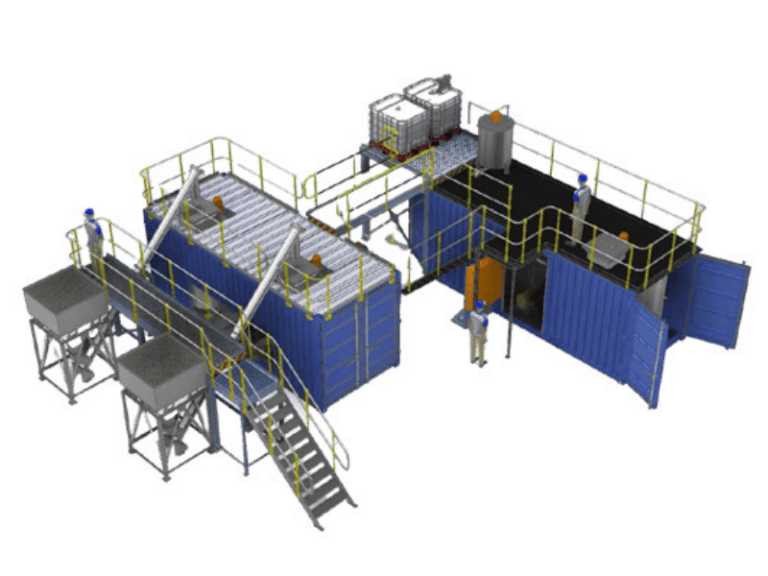

With the Emulsion Plants being modular in design we offer processes with two production outputs: The F1 plant, capable of producing 20 T of emulsion in an eight hour shift, or the F3 plant, with a production capability of 40 T per shift, which is a F1 plant with additional production and steam generation modules.

Most importantly, while all of our plants have been designed to be easily operated and maintained, they also include all the necessary safety controls to provide an operator-friendly work environment.

|  |  |

In case of emergencies, click here to contact our team for assistance.

Omnia disclaims all liability whatsoever, whether arising in contract, delict (including negligence) or otherwise in relation to the use of any products/solutions or services and all implied warranties, terms and conditions relating to the products/solutions or services (whether implied by statue, common law or otherwise), including (without limitation) any warranty, term or condition as to accuracy, completeness, satisfactory quality, performance, fitness for purpose or any special purpose, non-infringement, information accuracy, as between Omnia and you, are hereby excluded. Omnia specifically disclaims liability and will not be responsible for, any liability or damages, howsoever arising, resulting from the use or reliance upon the information in this document.

You assume sole responsibility for results obtained from the use of the products/solutions or services, and for conclusions drawn from such use.

We continuously update our technical data sheets to reflect the most current and accurate information based on the latest available data. As such, the information provided is subject to revision. We recommend regularly checking for updates to ensure you are accessing the most up-to-date technical details.