Equipment

Non-Electric

Initiation

Surface and Underground

Equipment

Non-Electric

Initiation

Surface and Underground

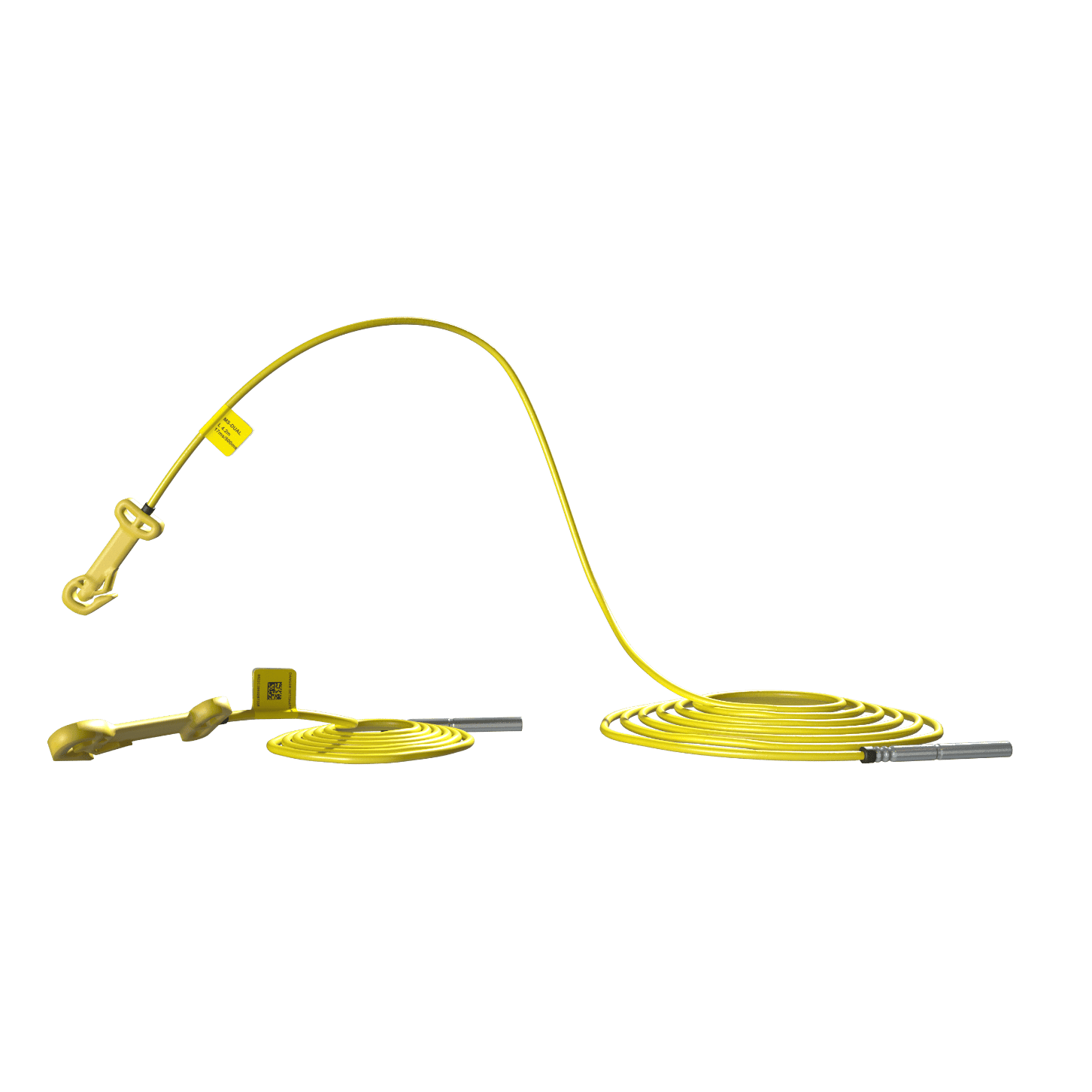

Viperdet MS Dual is a non-electric detonator assembly with a high strength in-hole detonator on one end and a low shrapnel surface detonator in a colour coded connector on the other.

A colour coded label marked with the specified delay is attached to the shock tube within 10cm of the connector.

Viperdet MS Dual is used for initiation of explosives in open-pit mines, underground non-coal and non-methane mines, quarries and construction works. Viperdet MS Dual detonators may be used in underground mines, where there is no coal dust and/or methane explosion hazard. The connector can hold up to 6 shock tubes and is designed to ensure easy connection, and reliable initiation while minimizing shrapnel damage to the shock tube.

Detonator strength: In-hole No. 8, Surface No. 3.

Shell material: Aluminium.

Shock tube: Triple extruded polyethylene exterior over surlyn inner.

Connector material: PE.

Nominal VOD of shock tube: 2000 m/s.

Resistance to hydrostatic pressure: 48 hrs at 1 MPa.

Maximum number of shock tubes inserted into a Viperdet Trunkline connector is six (6).

Primary initiation by electronic detonator, electric detonator, or shock tube starter.

Never:

Avoid pinching off shock tubes during loading and stemming.

For underwater blasting, please consult your BME Technical Representative.

Ground Temperature

This product may be used in ground temperatures up to a maximum of 65°C (150°F). If the application requires use outside of this temperature range please contact a BME Technical Representative for additional guidance.

| Delay times (ms) of Surface/In-hole detonators | Connector colour |

|---|---|

| 17/350 | Yellow |

| 17/500 | Yellow |

| 25/350 | Red |

| 25/500 | Red |

| 42/350 | White |

| 42/500 | White |

| 67/350 | Black |

| 67/500 | Black |

PE bags filled with bundles of 5 non-electric detonators with the same delay time. Number of detonators per box depends on length of the shock tube.

Shipping container

Cardboard box.

Cargo safety measures

Shipping containers are placed on a wooden pallet and secured with stretch film.

Remarks

Other packaging configurations are available. Contact your BME Sales Representative for options.

| Detonators in a bundle | Detonators in a box | Shock tube length (m) |

|---|---|---|

| 5 | 250 | 6 |

| 5 | 200 | 10 |

| 5 | 150 | 12 |

| 5 | 140 | 15 |

| 5 | 120 | 18 |

| 5 | 80 | 30 |

Shelf life

36 months from the date of production. Store under recommended conditions.

Storage conditions

Minimum storage temperature (- 45°C) and maximum storage temperature (+65°C). The product should be stored in its original packaging.

Disposal

Disposal of expired non-electric detonators and its packaging should conducted of by authorized personnel and/or companies.

Proper shipping name

Detonator assemblies, non-electric.

Class

1

Division

1.1 B (UN 0360).

1.4 B (UN 0361).

1.4 S (UN 0500).

In case of emergencies, click here to contact our team for assistance.

All rights reserved. To the maximum extent permitted by law.

Omnia disclaims all liability whatsoever, whether arising in contract, delict (including negligence) or otherwise in relation to the use of any products/solutions or services and all implied warranties, terms and conditions relating to the products/solutions or services (whether implied by statue, common law or otherwise), including (without limitation) any warranty, term or condition as to accuracy, completeness, satisfactory quality, performance, fitness for purpose or any special purpose, non-infringement, information accuracy, as between Omnia and you, are hereby excluded. Omnia specifically disclaims liability and will not be responsible for, any liability or damages, howsoever arising, resulting from the use or reliance upon the information in this document.

You assume sole responsibility for results obtained from the use of the products/solutions or services, and for conclusions drawn from such use.