January 27, 2022

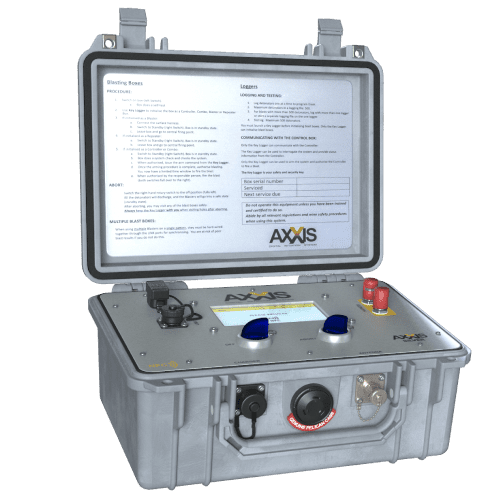

The AXXIS Silver electronic initiation system is the latest expansion of AXXIS technology. The AXXIS Silver electronic initiation system incorporates numerous handling, performance, and safety improvements built upon the highly successful AXXIS GII system. AXXIS Silver is a cost effective solution for users wanting to upgrade from the limitations and results of non-electric initiation to the flexibility and added blast performance realized by electronic initiation.

The AXXIS Silver electronic initiation system is designed for use in most general and specialized mining, quarrying, and construction blasting applications on the surface or underground. The AXXIS Silver electronic initiation system passes ARP 1717-1: The South African National Standard for the design and approval of EDD initiation systems for mining and civil applications.

All AXXIS Silver Blasting Boxes are the same. Each AXXIS Silver Blasting Box is configurable to a Blaster Box or a Controller Box to accomplish its required function. Blasting Box operation is simple, with double rotary switches for switching a box on, placing it in standby mode, and opening communications channels to fire the blast. Wireless communications are achieved through three selectable open-band frequency channels. Other frequency channels can be configured based on the country requirements.

AXXIS Silver Blasting Boxes configured as Blaster Boxes are placed at each blast site and connected to the surface wire harness. No power is supplied to the detonators until system arming from the Controller Box at blasting time.

Each Blaster Box can fire up to 800 detonators. In large single blasts where more than one Blaster Box is needed, the Blaster Boxes are hard-wired together using AXXIS link sets. Up to 2 Blasting Boxes may be linked together for a total combined firing capability of 1600 detonators in a single blast.

Only one Blasting Box may be configured as a Controller Box per blast. The Controller Box requires the presence of a Key Logger to authorise arming and firing of the system. On arming of the system with the Controller Box, each Blaster Box then powers up its detonators, and testing routines automatically start and continue until firing time. Detonators respond by exception, allowing a quick testing time and immediate warnings to the operator through the color screen on the Controller Box and the Key Logger.

A Blasting Box may be configured as a Combo Box. The Combo Box configuration is useful in quarry and construction blasting where the harness line-in line from the blast can be directly connected (hard-wired) into the Combo Box at the safe firing point.

The Blasting-Controller Combo Box requires the presence of a Key Logger to authorise arming and firing of the system. On arming of the system with the Blaster-Controller Combo Box, the detonators are powered up, and testing routines automatically start and continue until firing time. Detonators respond by exception, allowing a quick testing time and immediate warnings to the operator through the color screen on the Blaser-Controller Combo Box and the Key Logger.

Two types of AXXIS Silver system specific antennas are available. The short-range antenna can be used for line-of-sight distances up to 1200 m. Depending on frequency allocation, the long- range ET Plate antenna can be used for line-of-sight distances between 1500 m and 5000 m.

| Column 1 | Column 2 |

|---|---|

| Blasting Box Housing | Hard silver plastic |

| User Interface | Colour LCD with variable intensity and contrast setting |

| Screen Resolution | 2000 x 1500 pixels |

| Battery | 24-volt rechargeable Lithium-ion |

| Battery Capacity | 6000 mAh |

| Battery life dependent on the number of detonators in each blast | |

| Batteries are not user replaceable | |

| Blasting Box Mass | 2.1 kg |

| Maximum Detonators per Logger | 500 detonators per file |

| Maximum Detonators per Blasting Box in Blaster Box mode | 800 Detonators |

| Maximum Blaster Boxes per Controller Box | 2 Blaster Boxes |

| Maximum Detonators per Blast | 1600 Detonators |

| Controls | 2 rotary switches |

| Spring loading on the full-right position to fire a blast in Controller Box mode | |

| Communication Ports | Ports for antenna, charging, USB, harness wire and link cables |

| QR Code Authentication | |

| Wireless Communication | Wireless communication range between Blasting Boxes = 1000 m to 5000 m line of sight |

| Modem Frequency | 158 MHz or 433 MHz or 915 MHz |

| Resistance to Electrostatic Discharge | Electrostatic Discharge Immunity Test (+/- 8kV contact , +/- 15 kV air) |

| Electrical Fast Transient/Burst Immunity (+/- 2 kV) | |

| Operating Temperature | -30°C and +60°C |

| Storage Temperature | -40°C and +70°C |

AXXIS Silver Blasting Boxes may only be programmed, tested, and fired with AXXIS Silver Loggers and AXXIS Silver EDDs. Do not attempt to program, test, or fire Silver Blasting Boxes with other blasting equipment. Never mix electronic delay detonators and/or components from different manufacturers.

AXXIS Silver Loggers and Blasting Boxes need to be calibrated and serviced by BME qualified personnel or providers every 2 years.

Always use AXXIS harness wire to tie-in blasts. Do not substitute similar looking harness wire as the performance specifications may not be the same.

Although BME AXXIS Silver cables are engineered and constructed for challenging work environments, care should still be exercised when loading and stemming to avoid cutting or damaging downlines.

The Silver Blasting Boxes may be operated in temperatures from -30°C to a maximum of +60°C. If the application requires use outside of this temperature range please contact a BME Technical Representative for additional guidance.

Silver Blasting Boxes are robust electronic instruments that are engineered to be water and dust resistant (IEC 60529 IP65 and IP68) and drop shock resistant (IEC 60069-2-32: 1975). AXXIS Silver EDD Loggers are not waterproof – Do not submerge Silver Blasting Boxes in water.

Silver Blasting Boxes are robust electronic instruments that need to be used, charged, and stored with care. The Silver Blasting Boxe may be stored in temperatures from -40°C to a maximum of +70°C. Please consult with a BME Technical Representative for site specific guidance.

All rights reserved. To the maximum extent permitted by law:

Omnia disclaims all liability whatsoever, whether arising in contract, delict (including negligence) or otherwise in relation to the use of any products/solutions or services and all implied warranties, terms and conditions relating to the products/solutions or services (whether implied by statue, common law or otherwise), including (without limitation) any warranty, term or condition as to accuracy, completeness, satisfactory quality, performance, fitness for purpose or any special purpose, non-infringement, information accuracy, as between Omnia and you, are hereby excluded. Omnia specifically disclaims liability and will not be responsible for, any liability or damages, howsoever arising, resulting from the use or reliance upon the information in this document.

You assume sole responsibility for results obtained from the use of the products/solutions or services, and for conclusions drawn from such use.