BME Indonesia

MNK and BME Joint Venture Company (also known as KMB), is a joint venture that combines the local expertise of Multi Nitrotama Kimia (MNK) with the global innovation of BME Indonesia.

What sets us apart?

MNK and BME's collaboration leverages BME's cutting-edge technology and innovative products with MNK's extensive local networks, experience, and resources.

This enables us to deliver unparalleled blasting services and technical support, driving efficiency and safety in mining projects across Indonesia.

Together, we provide a unique and comprehensive suite of products and services tailored for both surface and underground mining operations.Operating across more than 10 projects throughout Indonesia, KMB is committed to delivering you superior blasting solutions.

Our commitment to superior blasting solutions improves the efficiency and safety of your mining endeavours.

Our Capability.

Complete licenses.

Indonesian market leader.

Established logistics network in Indonesia.

Strong customer base.

Comprehensive local knowledge.

Domestic production capabilities.

Experienced and loyal employees.

Fully Integrated Blasting Services

MNK and BME Joint Venture Company

Global footprint – physical presence in 25 countries.

40 years in operation.

Workforce of 4000 employees.

Unique explosives formulation.

Advanced research and development.

Comprehensive solutions for Underground and Surface Mines, including:

- Programmable Logic Controllers (PLCs), Mobile Manufacturing Units (MMUs) and On-Site Plant (OSP).

- Digital initiation systems.

- Digital recording and reporting.

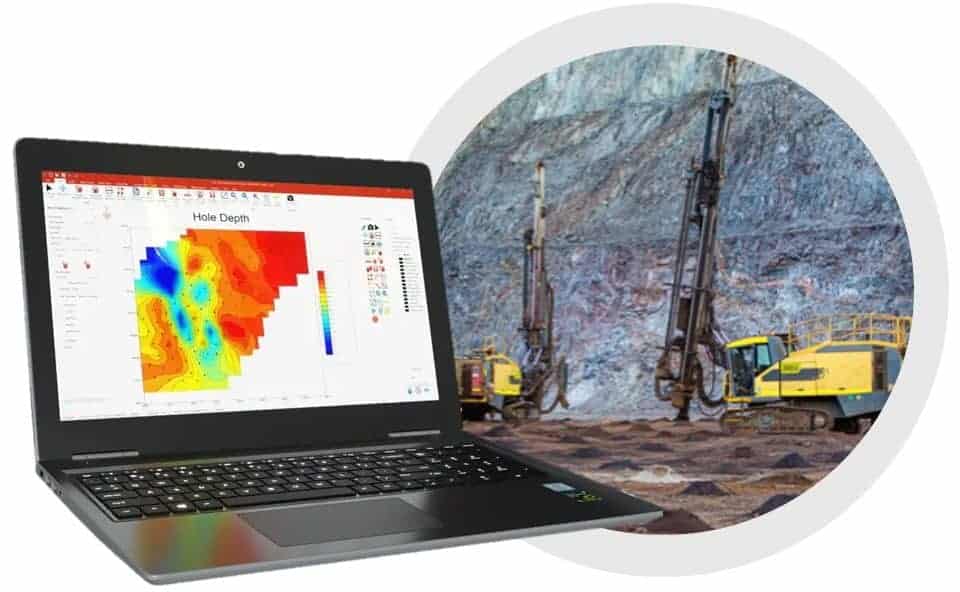

- Blast design software.

Our Facilities.

MNK and BME ensure a reliable supply chain throughout Indonesia. We have all the necessary licenses, as well as local manufacturing plants. We have a comprehensive customer distribution network, and our plants adhere to excellent safety and quality management systems.

Ammonium Nitrate Plant.

Established in 1990 and upgraded in February 2012, increasing supply capability to 145,000 MT per annum (approximately 30% of Indonesia’s demand). Our Ammonium Nitrate plant guarantees a reliable supply to meet the local market’s needs. The plant is situated in Cikampek, West Java, a 3-hour drive away from the Jakarta Tanjung Priok Seaport.

Non-Electric Detonator Assembly Centre.

Located in Handil, East Kalimantan, this facility assembles non-electric detonators, reducing Indonesia’s reliance on imported explosive accessories. The Centre produces up to 8 million pieces per annum. Built under International Standards for explosive warehouses, it is the biggest single magazine under one roof in Indonesia.

2 Automated AXXIS Electronic Detonator Plants.

A Cartridge Explosive Facility.

Non-electrics Assembly Plant.

MMU Manufacturing and Assembly.

Remote Emulsion Plants.

2 Central Emulsion Plants.

Ammonium Nitrate Plant.

2 Nitric Acid Plants - the newest in Africa.

Nitrophos Plant, CN (Calcium Nitrate).

Ammonium Nitrate Facility ANS (Ammonium Nitrate Solution) and ANCN (Ammonium Nitrate and Calcium Nitrate) Solution.

How we help:

Through it's joint venture company in Indonesia, BME and PT Kemitraan MNK BME (also known as KMB), combines the local expertise of Multi Nitrotama Kimia (MNK) with the global innovation of BME Indonesia.

Our comprehensive offering provides you with ongoing support that creates value across the blasting cycle.

Our Offering.

Together, KMB, MNK and BME are actively growing our presence in the region. We offer a full range of explosives products and manufacturing services to the Indonesian market.

Our current offering includes, but is not limited to:

1. Optimised Blasting Solutions

Our team has extensive field knowledge and experience to help you achieve safer, more efficient blasting.

a. Down the Hole (DTH)

Utilise Mobile Manufacturing Units (MMUs) to deliver high-quality reliable bulk explosives to blast holes.

b. Prime, Load, Tie, Shoot (PTLS)

Comprehensive prime, load, tie-up, and shoot solutions, for customers who require KMB’s team to perform a full blasting service. We provide the skills and resources to achieve the best blasting results.

c. Rock on Ground (ROG)

In this comprehensive blasting service, KMB takes full responsibility, from blast design to analysing fragmented rock (excluding drilling). This allows you to completely outsource this function. Value is measured by fragmentation quality and volume of broken rock.

d. Value-Added Project Optimization

For specialized projects, KMB can help you incorporate techniques to improve project efficiency.

e. Reactive Ground Management

Addressing and mitigating reactive ground conditions.

f. Blasting Consultancy

We offer technical services and solutions consultations with our experienced explosives engineering specialists.

2. Blast Performance Measurement

a. Velocity of Detonation (VOD) Measurement

Accurate detonation velocity analysis.

b. Vibration and Air Blast Monitoring

Ensure compliance and safety through meticulous monitoring.

c. Drone Data Capturing

Pre- and post-drill blast hole analysis and 3D face profiling.

3. Blast Analysis

a. Vibration Analysis

Utilise vibration data for monitoring and detecting issues.

b. Signature Hole Analysis

Detailed analysis for optimized blasting performance.

c. Fragmentation Analysis

Evaluate your blast outcomes to improve your future operations.

- On bench data blast management system.

- Accurate recording of hole loading data.

- Quality Assurance and Control (QA/QC).

1. Xplocharge Smart MMU

2. AXXIS Digital Initiation Systems

- On bench data blast management system.

- Accurate recording of hole loading data.

- Quality Assurance and Control (QA/QC).

1. Blastmap Blast Design

- Driller integration.

- Pre-blast predictive analysis tools.

- Blasthole loading.

- Timing design.

2. Xplolog

- Mobile device for hole and deck data capturing.

- Online reporting dashboard or data analysis and custom reporting.

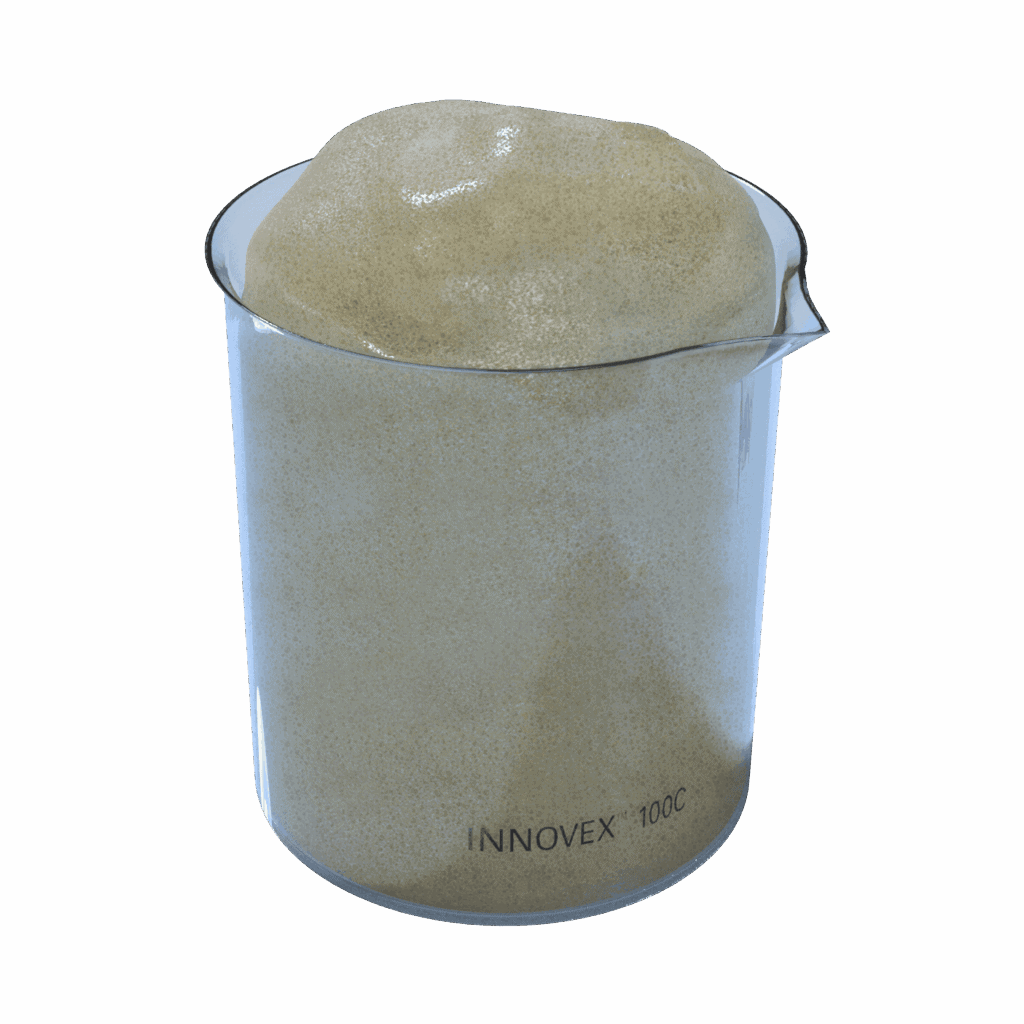

1. Emulsions

Our Emulsion Manufacturing Plant produces high-performance emulsions using pure diesel and used oil. We offer a variety of high-performance single- and dual-salt emulsions.

What makes our Emulsions better?

We use dual salt technology to create powerful emulsions that improve the efficiency, cost-effectiveness and performance of your blasting operations.

Dual salt emulsions, also known as ‘cold emulsion’, were first introduced by BME in South Africa in 1984. BME is renowned for its groundbreaking innovation in dual salt technology.

Benefits of Dual Salt Emulsions:

We use dual salt emulsion technology to avoid relying only on Ammonium Nitrate or Ammonia for producing our emulsions. This protects you from unpredictable price fluctuations and costly supply shortages.

We utilise Calcium Nitrate (CN) fertilizer in our emulsions for the following benefits:

- This product offers a compelling alternative, thanks to its plentiful availability.

- CN is a widely used chemical categorized as a fertilizer. Utilizing CN facilitates easy import and export, and reduces lead times in raw material procurement.

- Using CN has advantages like stabilizing ammonium nitrate solution and reducing the crystallization temperature of the oxidizer.

- Incorporating CN allows emulsion plants to operate at lower temperatures, reducing energy costs.

- CN enhances emulsion stability, extends shelf life, and provides energy output comparable to single salt formulations.

1. Mobile Manufacturing Unit (MMU)

2. Ammonium Nitrate Fuel Oil Truck (ANFO)

3. Emulsion Plant

Our Key Projects.

KMB is helping customers to achieve better blasting in the following areas across Indonesia:

- Alamjaya Bara Pratama

- Putra Perkasa Abadi – Borneo Indobara

- Adaro Indonesia

- Ganda Alam Makmur

- Hasnur Riung Sinergi – Bhumi Rantau Energi

- Hasnur Riung Sinergi – Energi Batubara Lestari

- Pamapersada Nusantara – Kideco Jaya Agung

- Pamapersada Nusantara – Asmin Bara Bronang

- Pamapersada Nusantara – Suprabari Mapanindo Mineral

- Pamapersada Nusantara – Berau Coal

- Riung Mitra Lestari – Energi Batu Hitam

- Riung Mitra Lestari – Multi Tambang Utama

- Petrosea – Multi Tambang Utama

- Riung Mitra Lestari – Marunda Graha Mineral

- Antareja Mahada Makmur – Perkasa Inakakerta

- Merdeka Copper Gold – Bumi Suksesindo

- Jakarta Head Office and Support Services

- Balikpapan Support Office

Latest News.

Read more:

BME Metallurgy drives green chemistry for sustainable mining

BME proves a unique solution for colloidal silica in leaching

Advanced blasting supports sustainable mining

African Mining Indaba in Cape Town – with Omnia Holdings company BME’s teams from its

BME Metallurgy drives green chemistry for sustainable mining

Environmentally responsible chemical practices demand an integrated approach from mines, across the mining value chain,

BME proves a unique solution for colloidal silica in leaching

Metallurgy has succeeded in developing and applying an innovative solution that promises potential in other

Contact Us

Head Office

Equity Tower 41st Floor, Suite E, Sudirman Central Business District (SCBD), Jl. Jend. Sudirman Kav. 52-53 Lot 9, Jakarta 12190.

Correspondence Address

GKM Green Tower, 3rd Floor Suite 303 Jl.

TB Simatupang Kav. 89G Jakarta 12520, Indonesia.

Telephone Help

(+62-21) 2787 1846

Email

info@mnkbme.com